LiquiTech® Sediment Filtration System

The LiquiTech® Sediment Filtration System removes sediment from your water that can damage pipes and other water-bearing equipment, degrade water quality, and encourage bacteria growth. With self-cleaning stainless-steel filters and a smart control system, our Sediment Filtration System is durable, sustainable, cost-effective, and water-efficient.

Key highlights:

- Protects pipes and equipment from sediment build-up and corrosion

- Self-cleaning stainless steel filters save time, money, and waste

- Durable, sustainable, and cost-effective

Benefits

- Long-term savings: Removing sediment from your water supply helps prevent premature damage to plumbing infrastructure. Your water-bearing equipment and pipes will last longer and require less maintenance time and money in the long run.

- Low maintenance: With its innovative stainless steel filters and self-cleaning technology, there are no filters to replace, saving staff time, money, and waste.

- Water-efficient: Our system uses little water, typically operating at 99% water efficiency.

- Remotely monitored: A remote monitoring system tracks and logs data 24/7, providing real-time diagnostics, troubleshooting, and reporting by LiquiTech engineers.

- Smart: A controller with a touchscreen display constantly monitors the status and operation of the system, initiating self-cleaning cycles when sediment build-up reaches a certain level and sending out alarm notifications if issues occur. Staff can easily access performance data, adjust setpoints, and manually control the system through the on-system digital display.

- Compact: Our system takes up minimal floor space and does not require storage of cartridges, sand, bags, or other consumables.

Case study

96.7% sediment reduction at Colorado hospital

High sediment levels in incoming water supply caused pinhole leaks throughout piping system. Sediment filtration reduced sediment levels by 96.7%, helping the hospital avoid $80K+ in pipe replacement costs.

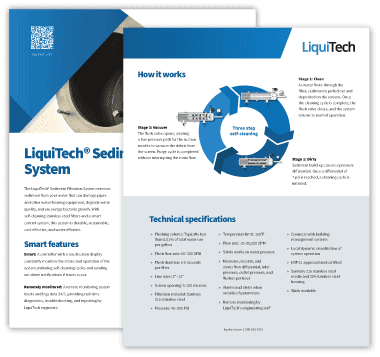

Download product specs

Want to learn how the technology works or see product specifications? Fill out the form below to download our Sediment Filtration System product brochure. For engineering and design tools, click here.

Explore more solutions

Contact us

Our experts are ready to answer your questions or help you get started. Call us at 800.635.7873 or fill out the form below.